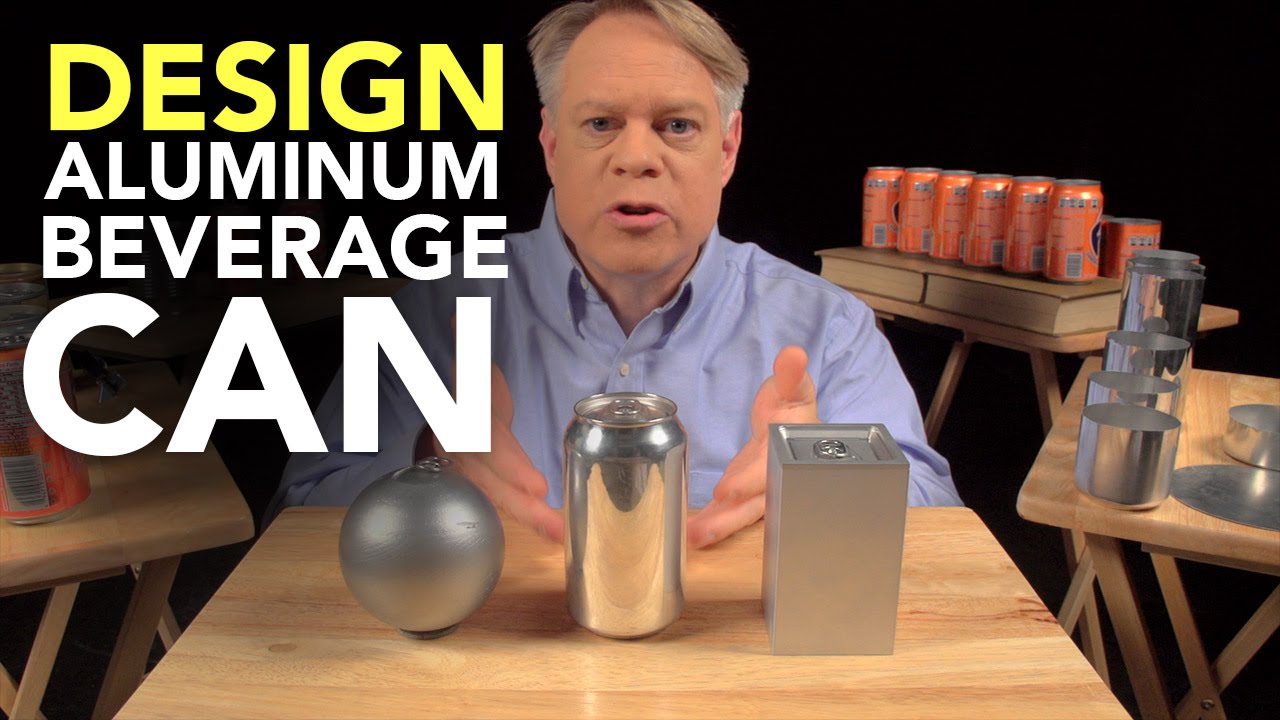

Bill details the engineering choices underlying the design of a beverage can. He explains why it is cylindrical, outlines the manufacturing steps needed to created the can, notes why the can narrows near it lid, show close ups of the double-seam that hold the lid on, and details the complex operation of the tab that opens the can.

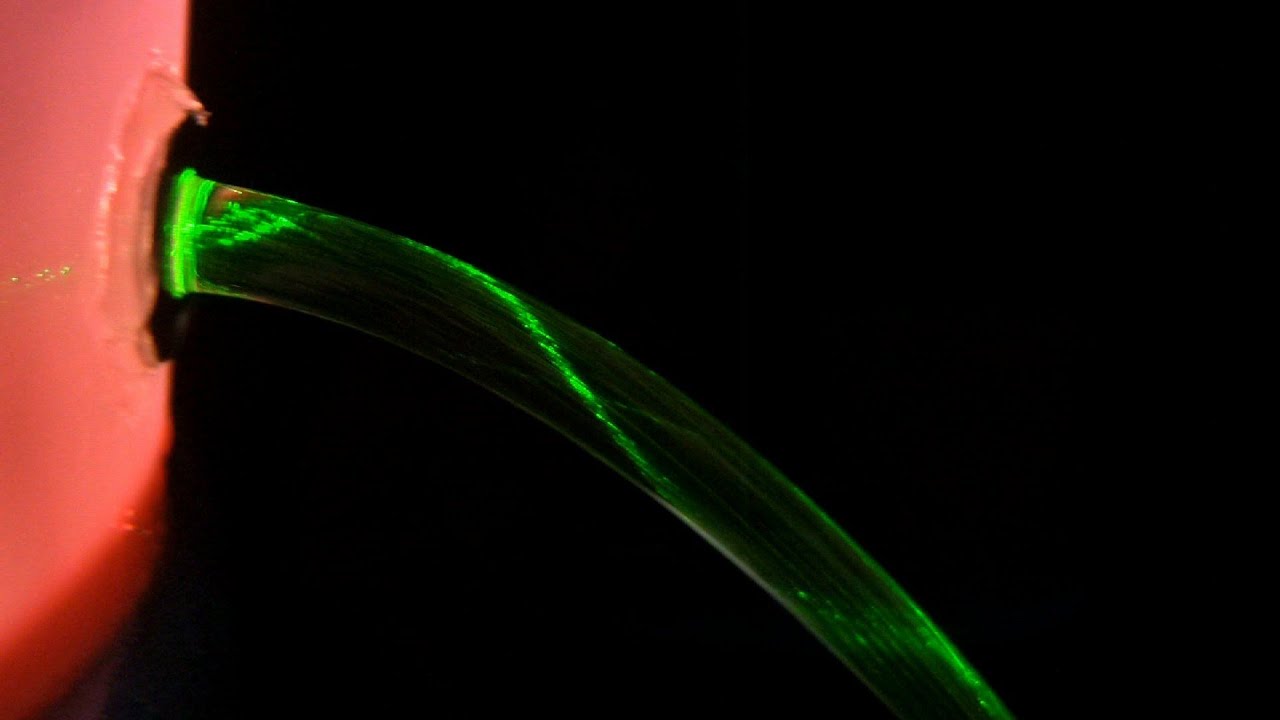

Bill uses a bucket of propylene glycol to show how a fiber optic cable works and how engineers send signal across oceans.

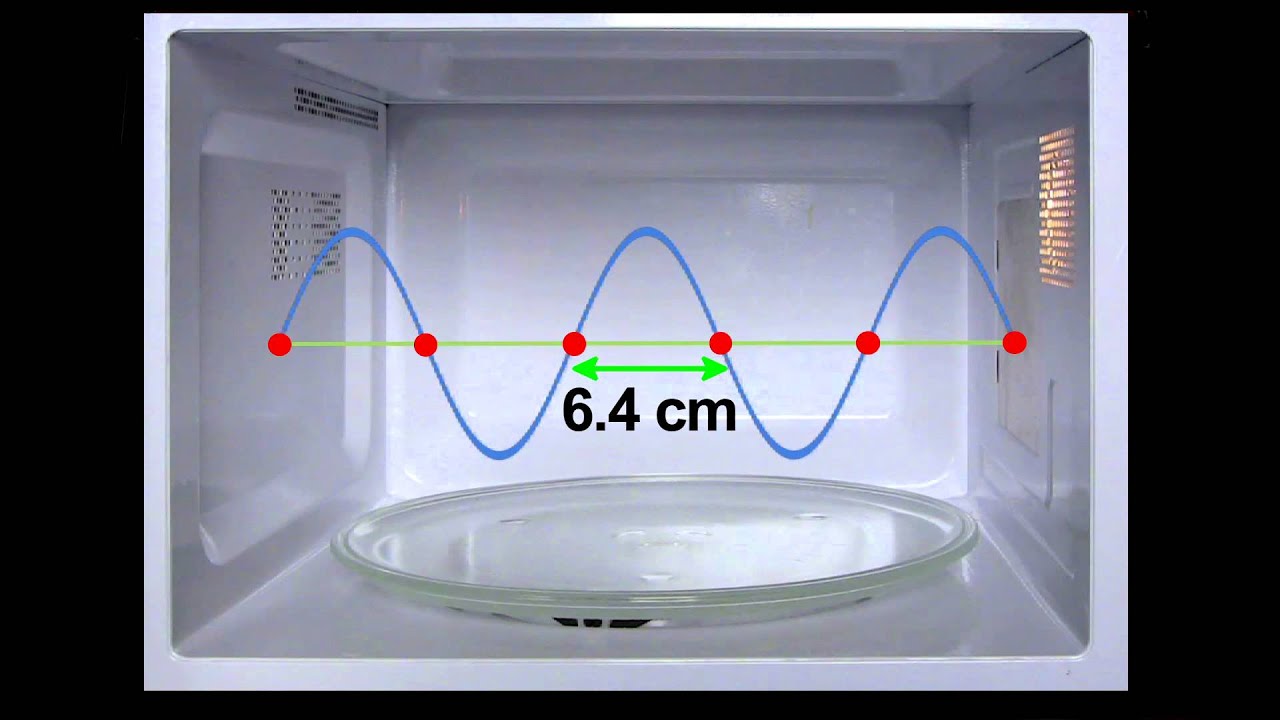

Bill details how a microwave oven heats food. He describes how the microwave vacuum tube, called a magnetron, generates radio frequencies that cause the water in food to rotate back and forth. He shows the standing wave inside the oven, and notes how you can measure the wavelength with melted cheese. He concludes by describing how a magnetron generates radio waves.

Bill takes apart an LCD monitor and shows how it works. He explains how it uses liquid crystals, thin film transistors and polarizers to display information.

In 1976 Sony introduced the Betamax video cassette recorder. It catalyzed the "on demand" of today by allowing users to record television shows, and the machine ignited the first "new media" intellectual property battles. In only a decade this revolutionary machine disappeared, beaten by JVC's version of the cassette recorder. This video tells the story of why Betamax failed.

Bill takes apart a smartphone and explains how its accelerometer works. He also shares the essential idea underlying the MEMS production of these devices.

Bill reveals how "queueing theory" - developed by engineers to route phone calls - can be used to find the most efficient arrangement of cashiers and check out lines. He reports on the work of Agner Erlang, a Danish engineer who, at the opening of the 20th century, helped the Copenhagen Telephone Company provide the best level of service at the lowest price.

Bill opens up a computer hard drive to show how it is engineered. He describes how the "head" reads the magnetic information on the disk; reveals how a voice coil motor and a slider controls the position of that head. He also discusses how smooth a disk must be, and briefly mentions a mathematical technique that allows engineers to pack more information on a drive.

Bill reveals the engineering design of a NERF blaster, including how it shoots only one dart at a time using a novel air restriction mechanism.

Bill shows how the three key characteristics of laser light - single wavelength, narrow beam, and high intensity - are made. He explains the operation of a ruby laser - the first laser ever made - showing how electronic transitions create stimulated emission to give coherent light, and then how the ends of the ruby cavity create a narrow wavelength highly collimated beam.

The amazing everyday wristwatch: We never think about it, but only because engineers have made it so reliable and durable that we don't need to. At its heart lies a tiny tuning fork made of the mineral quartz. In this video Bill takes apart a cheap watch and shows extreme close-ups of the actually tunings fork. He explains how the piezoelectric effect of quartz lies at the heart of the watch's operation.

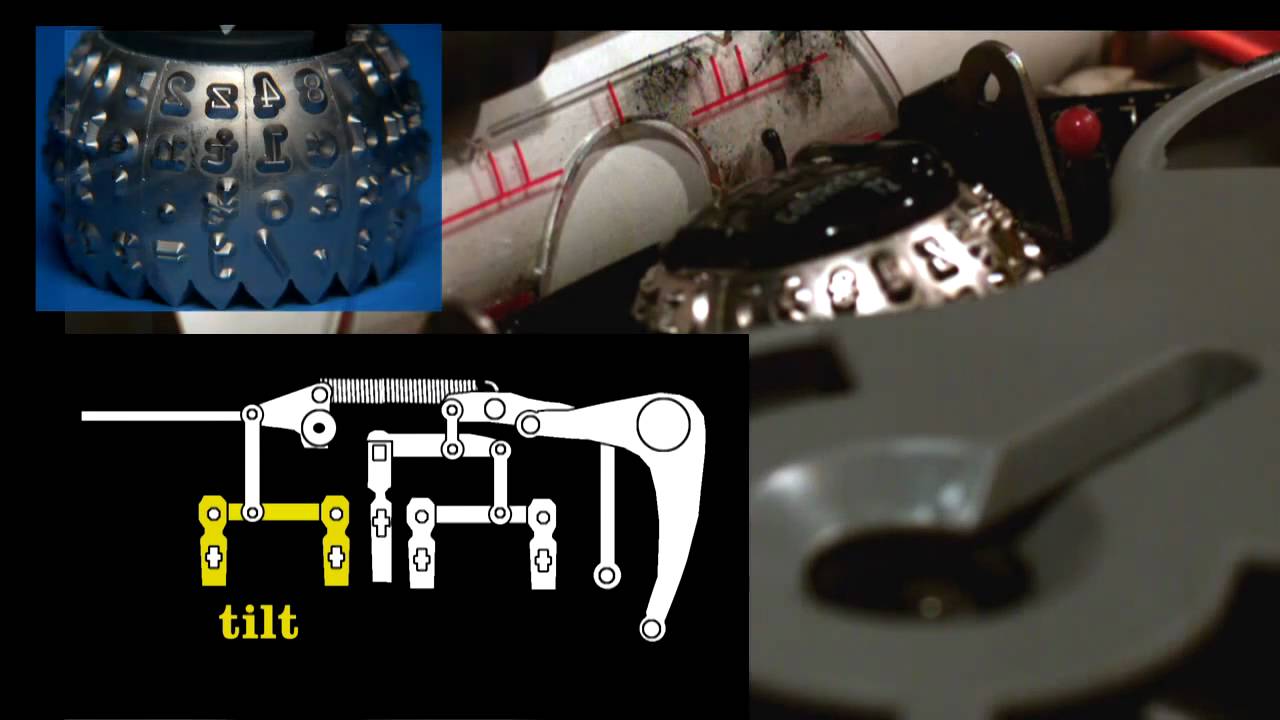

Using slow motion video Bill Hammack, the engineer guy, shows how IBM's revolutionary "golf ball" typewriter works. He describes the marvelous completely mechanical digital-to-analogue converter that translates the discrete impulse of the keys to the rotation of the type element. (This is the typewriter featured on the television series Mad Men.)

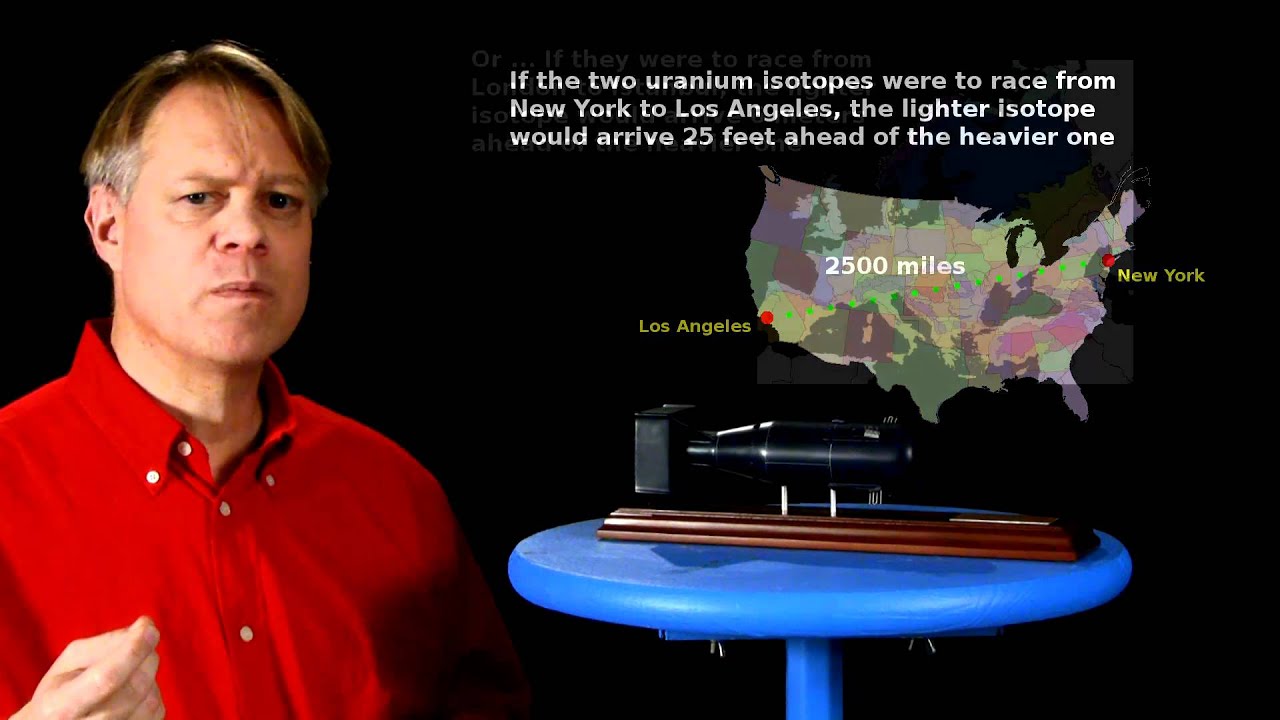

Bill explains that the hardest step is making the proper type of uranium. Weapons and power plants require uranium that contains a greater amount of the isotope uranium-235 than found in natural uranium, which is mostly uranium-238. He outlines the key difficulty in separating the two isotope: They have nearly identical properties. He explains the two key methods for separation: Gas diffusion and centrifuges.

Bill details the key engineering principles underlying plastic injection molding. He describes its history and, then, reveals the intricate details of the process. He shows viewers where to found, on any injection-molding product, the markings created by injection molding. He closes with a description of the one of the finest examples of the injection molding: the Lego brick.

Bill describes how metals like aluminum and titanium are made resistant to corrosion by growing an oxide layer into the metals. These is the same process used on many Apple products.

Bill shows the world's smallest atomic clock and then describes how the first one made in the 1950s worked. He describes in detail the use of cesium vapor to create a feedback or control loop to control a quartz oscillator. He highlights the importance of atomic team by describing briefly how a GPS receiver uses four satellites to find its position.

Bill shares fascinating images and information gleaned from the 1909 to 1911 editions of the Journal The Engineer. It includes photos of the construction of the Titanic and its twin the Olympic, the launching of these Olympic-class ships, and accidents that occurred. The video includes engineering details of the ship's engines, steering mechanism, and propellers.

Bill takes apart a coffee maker to show how hot water is pumped through it using a "bubble pump." The use of this pump reflects an engineer's choice to have only one heating element to lower the cost.

Bill takes apart an incandescent to show how the tungsten filament is made. He shows it in extreme close-up and also discusses the material processing needed to produce ductile tungsten.

Bill opens up a vintage "black box" from a Delta airlines jetliner. He describes how the box withstands high temperatures and crash velocities because it is made from Inconel: A superalloy steels that is used in furnaces and others extreme environments. The flight data recorder he shows is a Sundstrand FA-542 and was likely used on a DC-9 in the 1970s, although it could have been used as late as 1988 on a Boeing 727.

Bill takes apart a smoke detector and shows how it uses a radioactive source to generate a tiny current which is disrupted when smoke flows through the sensor. He describes how a special transistor called a MOSFET can be used to detect the tiny current changes.

Bill takes apart a digital camera and explains how its captures images using a CCD (charge coupled device). He also shares how a single CCD is used with a color filter array to create colored images.

Bill uses a replica of the point contact transistor built by Walter Brattain and John Bardeen at Bell Labs. On December 23, 1947 they used this device to amplify the output of a microphone and thus started the microelectronics revolution that changed the world. He describes in detail why a transistor works by highlighting the uniqueness of semiconductors in being able to transfer charge by positive and negative carriers.

Bill uses a pile of old cell phones to show the seven basic design constraints that shape a mobile phone.

Bill tears apart a film projector to reveal the amazing mechanisms used in the pre-digital age to trick the mind into seeing a moving image. He uses high speed photography and animations to show how the projector moves the film intermittently, how a shutter strategically blocks light as the film moves, and how the photo sensor reads the sound. He explains how all these mechanisms are synced.

Bill explains the essential principles of a lead-acid battery. He shows the inside of motorcycle lead-acid battery, removes the lead and lead-oxide plates and shows how they generate a 2 volt potential difference when placed in sulfuric acid. He explains how the build up of lead sulfate between the plates will make the battery unusable if it discharged completely, which leads him to a description of how to make a deep cycle battery used for collecting solar energy.

Bill reveals the stunning engineering underlying the design of a diaper. He describes the five layers of a diaper, including the superabsorbent polymer in the diaper's core. He illustrates the action of this polymer with a stunning demonstration using a single bead of polymer: it soaks up enough water to grow from a diameter of 4 mm to nearly a half inch.

Bill describes the Alignment Optical Telescope used in the Lunar Module on the Apollo missions to the moon. This telescope took star sightings which were used to align the Module's guidance system. Bill shows how the telescope used an Archimedes spiral inscribed on its eyepiece to replace the heavy motors, worm gears, and rigid tracks used in a traditional sextant -- this shaved weight from the Lunar Module and allowed it to carry more fuel.

Bill reveals the engineering inside a toy music box. He describes how the comb is mass manufactured, details the spring, gears and governor that drive the box, and shares some history of early music boxes. Outtakes are included at the end of the video.

Bill reveals the operation and engineering design underlying the famous drinking bird toy. In this video he explores the role played by the water the bird "drinks," shows what is under the bird's hat and demonstrates that it can operate using heat from a light bulb or by "drinking" whiskey.

This companion video to Bill's book Fatal Flight brings vividly to life the year of operation of R.101, the last great British airship—a luxury liner three and a half times the length of a 747 jet, with a spacious lounge, a dining room that seated fifty, glass-walled promenade decks, and a smoking room.

Bill demonstrates the temperature-dependent shape memory of nitinol metal. He explains how "twinning" in the crystal structure of nitinol produces the memory effect. He shows a nitinol-based engine that is powered by temperature differences. He closes the video with a description of superelasticity, a phenomenon related to the memory effect, which he demonstrates with a cardiac stent.

This video contains a short announcement about the companion book for engineerguy series #4 (which was published in 2012) plus outtakes.